Cleaning cutters and e file bits

It is necessary to remove material particles from the nozzle. It is made to make the cutter last longer and a preparatory stage before sterilization. E file bits tips should be thoroughly cleaned – with proper care, and they will serve no worse than diamond ones. The same can be said for steel and carbide e file bits – if cleaned correctly, they will dull less and remove material better.

Cleaning can be done in three ways:

- In a dental washer. To do this, you must first rinse the nozzles in water, place them in the apparatus on special stands and process for at least five minutes at 90 degrees Celsius.

- Manually using a plastic or brass brush under running water. This is the easiest and most affordable way, but it takes time.

- In an ultrasonic sterilizer (despite the name, this device is designed specifically for cleaning nozzles, and not for sterilization). Just as in the first case, the cutters must be rinsed before cleaning, then placed on special stands so that they do not touch. Be sure to check with your retailer to make sure ultrasonic cleaning is right for your attachments.

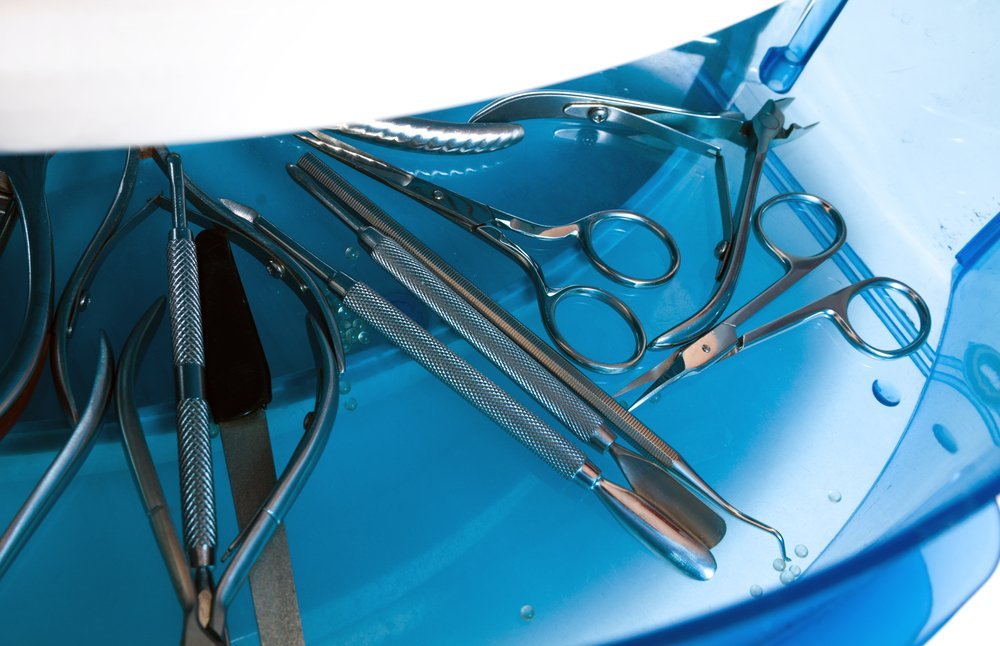

Sterilization of nail cutters

At this stage, the final destruction of all microorganisms occurs. There are three main methods for sterilizing cutters:

- Autoclaving – steam sterilization. It is mainly used for cutters that come into contact with blood and wounds, as well as penetrate under the skin. It is almost impossible to give general recommendations on the use of an autoclave – it is necessary to study the instructions for a specific instrument and follow it carefully.

- Thermal sterilization – processing in a dry heat cabinet. Suitable for those tips that have not been used invasively. You need to sterilize completely dried cutters to prevent corrosion, and carefully follow the instructions for the device. And remember: the time indicated in it is counted from the moment of heating to the desired temperature.

- Liquid sterilization is carried out using the latest generation of antiseptics and disinfectants (for example, “Multidez”). The main nuance is not to overexpose the cutters in the solution.

Storage of diamond, carbide, ceramic, corundum cutters

It would help if you stored the cutters in unique stands to protect them from moisture, dust, damage and contact with the skin. Ideally, keep the tips in an upright rack in a UV sterilizer.